In the 1920s the US Army designed its very first aeroplane cockpit.

It was a task they had never had to do before, so they needed to approach it logically.

They wanted something that could be used by as many pilots as possible – so they aimed straight down the middle.

To start with, they measured the physical dimensions of their male pilots. Then, they worked out the mean average for ten vital measurements, including pilot weight, height, and the length of their arms and legs.

With this information the US Army engineers determined the placement for cockpit features such as the pilot controls, how far back the seat needed to be, and the distance to the pedals.

They then built a cockpit perfectly suited to fit this ‘average pilot’ and installed it in all their planes.

This approach seemed to have worked well until the 1940s when, because of the Second World War, hundreds of new pilots had to be recruited in a rather short time frame.

The US Air Force (USAF) was formed in 1947 as an offshoot from the main Army – but the separation from the Army, coupled with the expansion in the number of pilots in their ranks, saw a big problem arise…

…their pilots kept crashing their planes!

For a few years, the high death rate for pilots was a bit of a mystery.

The engineers said the planes were mechanically sound, while the pilots stuck by their training and were convinced it wasn’t down to their own errors.

Then, someone had a bright idea.

These pilots were working out of cockpits designed decades ago – and the ‘average American’ was sure to have grown since then!

So, USAF researchers were handed the task of finding the ‘new normal’. In 1950 they measured over 4,000 pilots, taking the same ten measurements.

During the process, however, one young researcher called Gilbert S. Daniels thought it would be interesting to work out just how many of the US pilots actually were ‘average’.

To his surprise, not a single one was deemed ‘average’ in all ten measurements!

Not only that, when he took just three measurements, only 5 per cent were ‘average’ for all three.

By trying to design a cockpit suited to every one of their pilots, it seemed that the US forces had instead been using cockpits fit for nobody.

With the small pilot ranks during the first 20 years, however, there hadn’t been a large enough group to see the problem.

After being made aware of this, the USAF responded quickly and designed adjustable parts to the cockpits.

The update proved incredibly effective, and saw pilot performance levels shoot up and the death rate come firmly down.

This tale is a great example of why a one-size-fits-all approach to design doesn’t really work.

The USAF had the right idea – trying to build something that fits as many people as possible – but were actually making it for just one person.

What we can learn from this is the following: people come in all different shapes, sizes and abilities.

The philosophy behind the USAF’s attempts at creating a cockpit (even though they were, at first, unsuccessful), should be the same for designing anything likely to be used by a wide range of people.

This includes buildings – and with this in mind, architectural ironmongers should be familiar with ‘inclusive design‘.

Inclusive design helps one consider how people of all ages and abilities might interact with the environment they are being presenting with, and then fitting it accordingly with suitable features.

While the USAF used adjustable parts, for building designers this means architectural ironmongery.

The British charitable organisation the Design Council is a champion of inclusive design. They place great emphasis on design that “aims to remove the barriers that create undue effort and separation. It enables everyone to participate equally, confidently and independently in everyday activities.”

This thinking is especially important when it comes to public buildings such as hospitals or schools, where one must consider how to make an ‘inclusive environment’ that provides access to as many people as possible.

As far as architectural ironmongery goes, the main groups that should be to consider when fitting a building include (but are not limited to):

These groups should be considered an integral part of the design process – and, by meeting their needs, a building will perform better for all users.

Of course, some elements of inclusive design might help many groups at once. For example, the installation of ramps for entrance-point access to a building can be used by wheelchair users, families with pushchairs, or even delivery drivers dropping off large items.

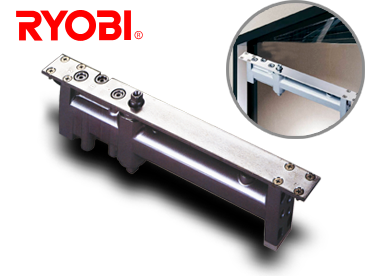

Some of the most common solutions for inclusive design that might be included for this purpose in an architectural ironmongery schedule are lever handles – preferably at 900mm above floor level – or automatic door closers.

The Chartered Association of Building Engineers has laid out a set of five ‘guiding principles’ when it comes to inclusive design in buildings:

As well as this, a useful resource for architectural ironmongers to possess is BS 8300:2009 – the official British Standards document for the ‘Design of Buildings and Their Approaches to Meet the Needs of Disabled People’.

This document contains a wealth of information on the building of an ‘accessible environment’ for disabled people specifically, but the recommendations can be beneficial across the board.

Remember – inclusive design is good design.

If you have any questions about inclusive design and architectural ironmongery, or wish to discuss our range of products that could be used in such a project, don’t hesitate to get in touch with JB Architectural Ironmongery.

We have over 50 years of experience in the industry and combine fantastic customer service with the best possible prices.

Give us a call on 01273 514 961 or head to our contact page to use our contact form.